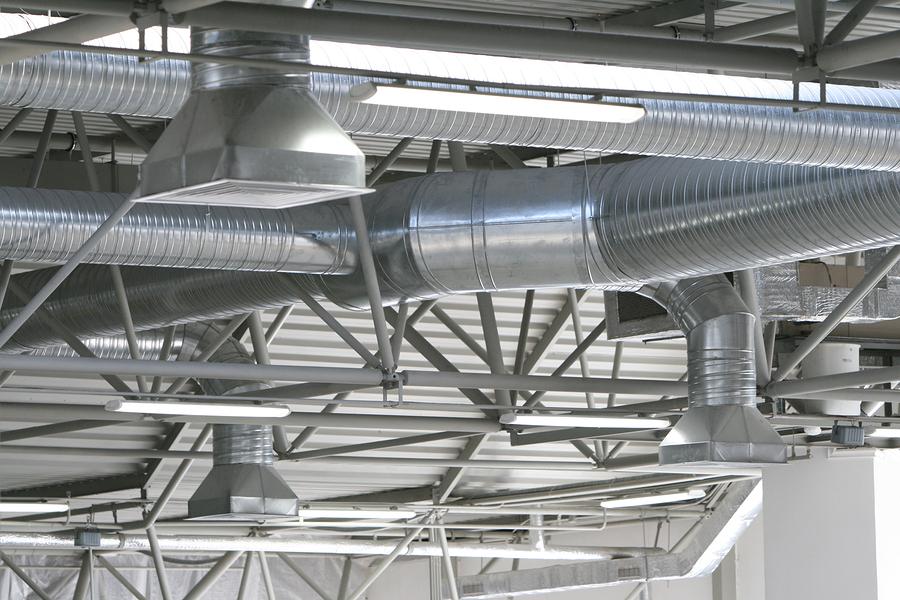

What is Fabricated Sheet Metal Used For in HVAC?

Fabricated sheet metal is commonly used in the ductwork of HVAC systems. Traditional ductwork is installed in commercial and industrial buildings for the heating and

Fabricated sheet metal is commonly used in the ductwork of HVAC systems. Traditional ductwork is installed in commercial and industrial buildings for the heating and

Average repair costs for an AC unit would depend on the type of repair needed, and how complicated it may be to perform. Repairs can

There are a few different situations where emergency plumbing services would be needed. But probably the most popular would be when you have a flood

There are many good and bad plumbers working in San Jose, so it is important to spot the good ones. You want to pick out

Another few years have passed and now it’s time for you to perform maintenance on your HVAC system. It takes time and money, and then

Air conditioning problems aren’t avoidable. The age of the system often determines the frequency of the repairs needed; however, a service contract may be the

Finding a reputable plumbing, process piping and HVAC contractor requires more than comparing bottom line prices and being moved by creative marketing. Here are three

When adding a new unit or expanding the additional system, ductwork replacement may be necessary. The process requires careful planning and coordination, so this alone

Indoor climate control provides more than just a comfortable temperature. In hot areas, a broken AC can lower productivity. Tech installations and labs also need

When airflow seems less than optimal and performance starts to drag, it may be time to repair the unit. Repair costs vary depending on the