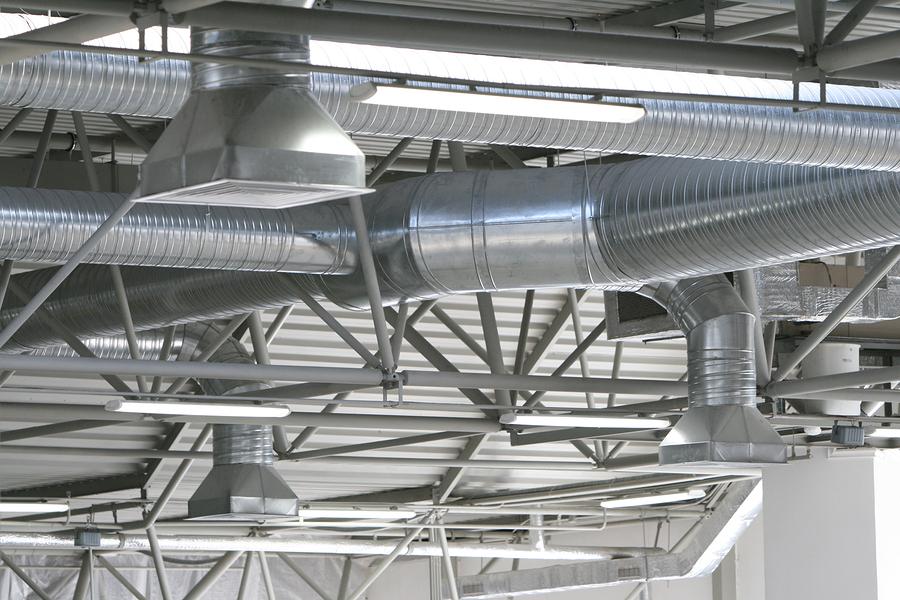

What’s the Average Price of an HVAC Compressor?

The compressor for an HVAC unit is an essential component to ensure that it runs as it should, but replacing it is rarely cheap. That doesn’t mean that you should simply ditch your HVAC system if it’s not working as it should. Here’s what you need to know about having an HVAC compressor replaced so