What To Look For In a New Construction Contractor

It’s a beautiful day and as you settle into your morning routine at the office, sipping on your second cup of java your office line

It’s a beautiful day and as you settle into your morning routine at the office, sipping on your second cup of java your office line

Average repair costs for an AC unit would depend on the type of repair needed, and how complicated it may be to perform. Repairs can

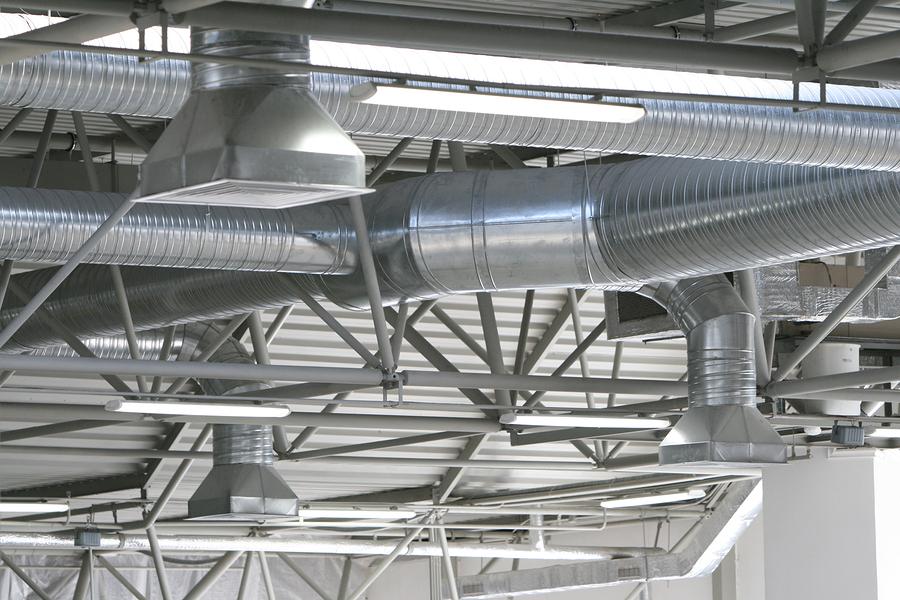

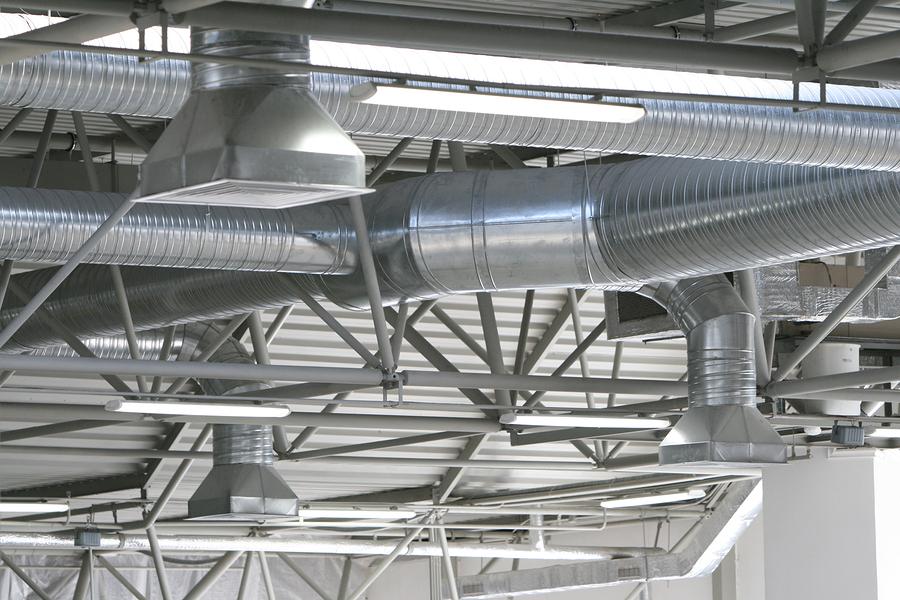

When adding a new unit or expanding the additional system, ductwork replacement may be necessary. The process requires careful planning and coordination, so this alone

Indoor climate control provides more than just a comfortable temperature. In hot areas, a broken AC can lower productivity. Tech installations and labs also need

When airflow seems less than optimal and performance starts to drag, it may be time to repair the unit. Repair costs vary depending on the

You may have an older HVAC unit that’s causing you some problems. Older heating/cooling appliances can be tricky when determining what’s wrong with them. Pinpointing

When you are outside, you can breathe fresh air from all directions. In a building, you might receive the majority of your air from your

As with many home repairs, changing a thermostat might seem like it requires a specialist. Whether adjusting your current aging thermostat has become a guessing

Custom sheet metal fabrication involves cutting and bending a metal sheet that is typically less than ¼ inch thick. Custom sheet metal fabrication is needed

The central heating, ventilation, and air-conditioning (HVAC) system that serves your facility is important to your operations in the summer months, but it can take