What to Look For In An Industrial Heating And Cooling Service Company

Finding a reliable Industrial and cooling service company can be challenging. It is crucial to avoid mistakes commonly made like getting tricked into purchasing the

Finding a reliable Industrial and cooling service company can be challenging. It is crucial to avoid mistakes commonly made like getting tricked into purchasing the

If plumbing is not properly done, it can cause premature failure or injury. In the long run, it is more cost effective to hire a

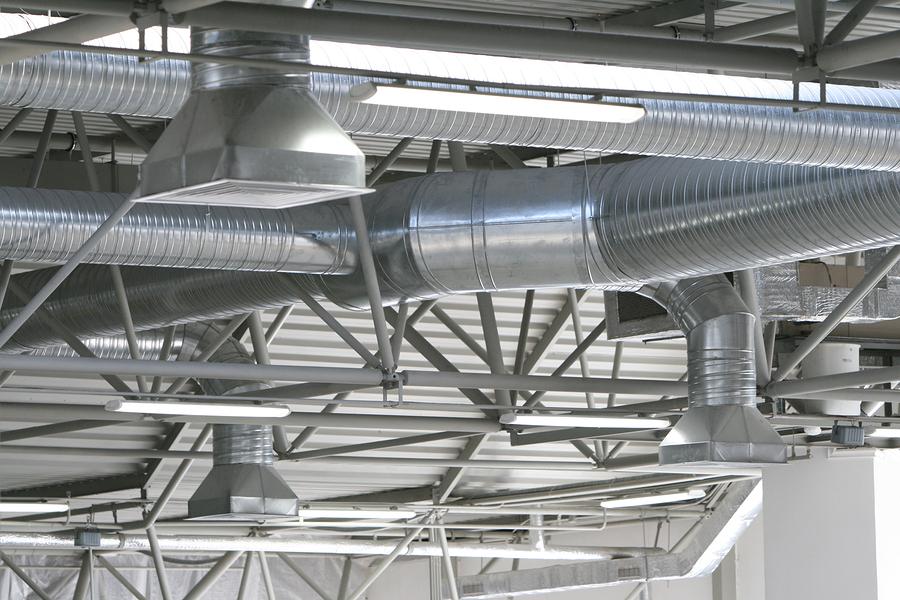

No matter what your business specialty may be, the HVAC system throughout your facility can affect your company. Lack of proper maintenance of your heating,

Converting your facility to solar power is a cost effective way to power your business. There are several steps to convert your facility’s electricity over

If you have spent any length of time in California, then chances are you will deal with an HVAC contractor sooner or later. Like everyone

Whether it is earthquakes on the West Coast, tornadoes through the Midwest, or devastating floods in the Southeast, or fire emergencies anywhere in the country,

After a long, cold winter, spring is finally here, and soon it will be time to crank up the AC to keep your home comfortable

Environmental heating and cooling is an objective for companies aiming to be better corporate citizens. Investing in heating and cooling systems can help a company

Choosing the right company to provide your HVAC tuneup is crucial. A regular heat and air tuneup is vital when it comes to keeping equipment

You know your air conditioning system, and sometimes you get that feeling that something is not quite right. If you have started to see a