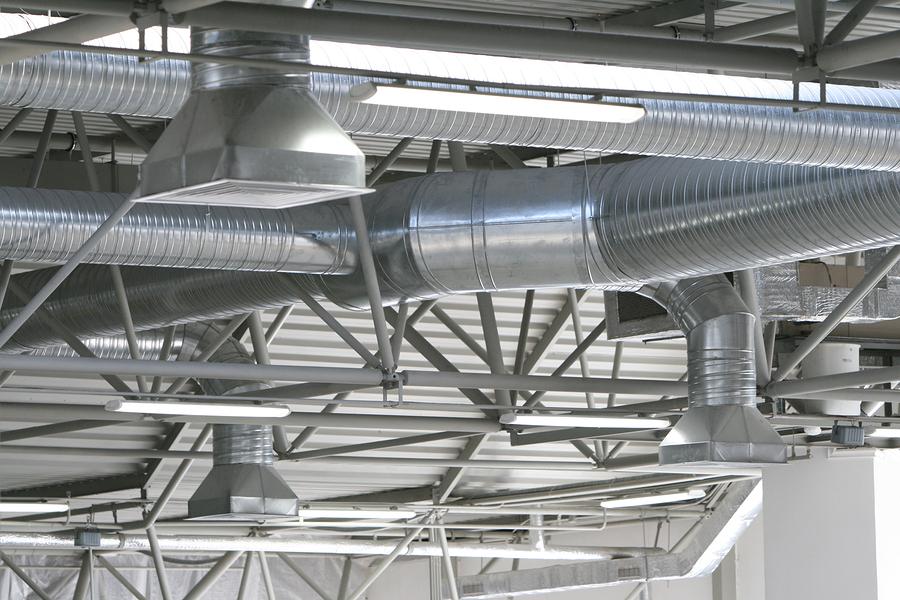

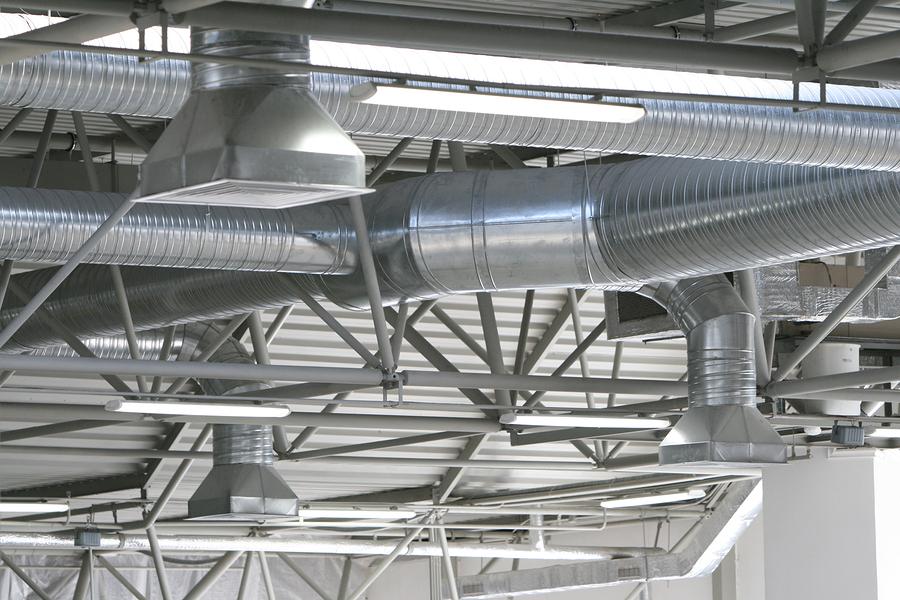

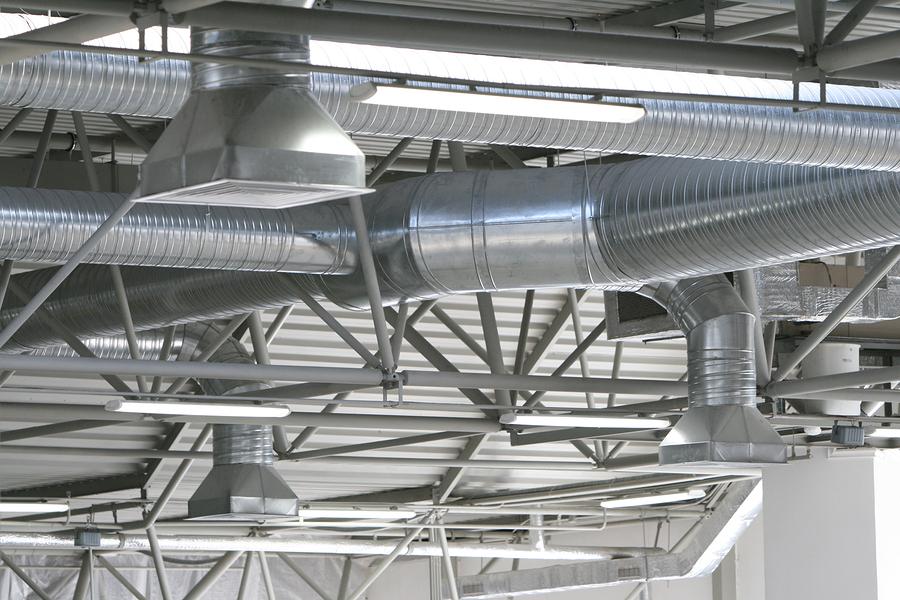

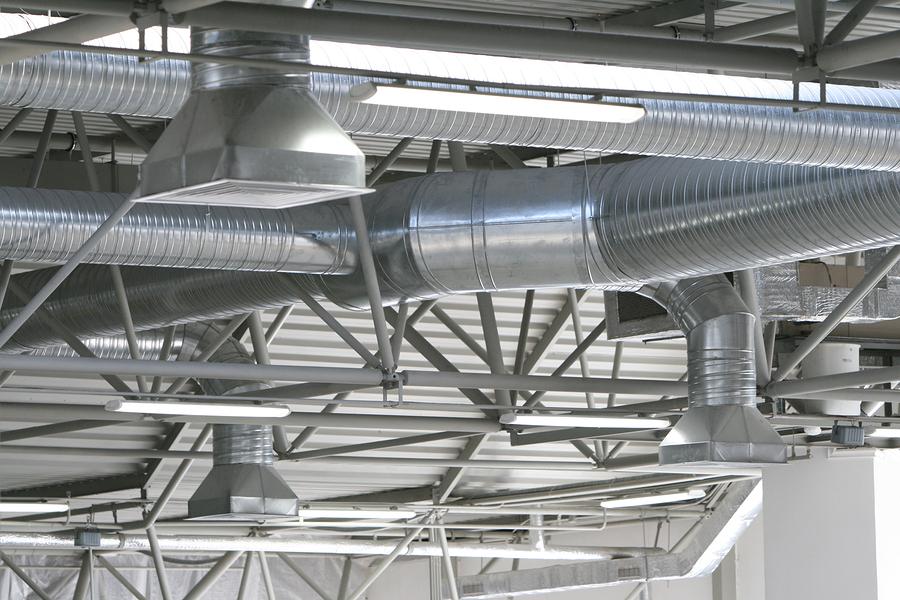

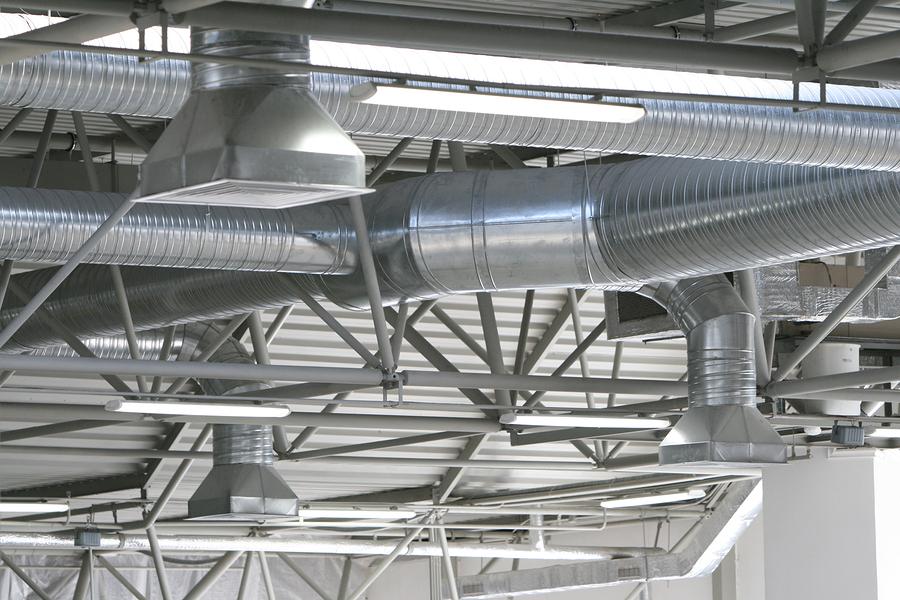

How Does Commercial Ductwork Differ from Residential Ductwork?

The primary objective of an HVAC system is to heat and cool the environment where it has been installed. For this to happen, the system

The primary objective of an HVAC system is to heat and cool the environment where it has been installed. For this to happen, the system

After you have your furnace or air conditioning unit serviced, you expect that it will operate efficiently and that the environment inside will be comfortable.

In small commercial buildings that have relatively simple layouts, standard ductwork tends to be sufficient for ensuring the acceptable delivery of heated and cooled air.

Each batch of sheet metal is made to differing levels of strength, size, and thickness depending on the exact performance tests it has to pass.

Fabricating custom ductwork is necessary to make sure that your ducts are connected right and customized to your unique home. A custom heating and air

When installing ducts in a facility, the type of material that goes into these systems is often overlooked. However, one of the most important elements

Most homeowners hire professional technicians to repair their HVAC units. When you want to save money, you might wonder if you have what it takes

Air quality is one of the defining features of a workspace. Fresh, clean, well-filtered air is a necessary part of a positive, peaceful, and ultimately

Ductwork is an important part of your heating and air conditioning set up. Ductwork is used for distributing air throughout your home once it has

A new air conditioning unit can be a big expense for your home or business, but an old, inefficient unit incurs frequent repair costs and