Can You Get Customized HVAC Sheet Metal Fabrication for Uniquely Designed Systems?

When it comes to customized HVAC sheet metal fabrication for uniquely designed systems, this option is not only available but also recommended by most HVAC

When it comes to customized HVAC sheet metal fabrication for uniquely designed systems, this option is not only available but also recommended by most HVAC

After you have your furnace or air conditioning unit serviced, you expect that it will operate efficiently and that the environment inside will be comfortable.

Industrial pipes must be strong and durable enough to last for decades of regular use. These pipes are built into walls inside of houses, installed

For all processing facilities, being able to get product, byproducts, or feedstock from one point to another in a timely and reliable fashion is critical.

Choosing the right HVAC system for your business is a key part of keeping your employees cool, protecting sensitive IT equipment, and ensuring high levels

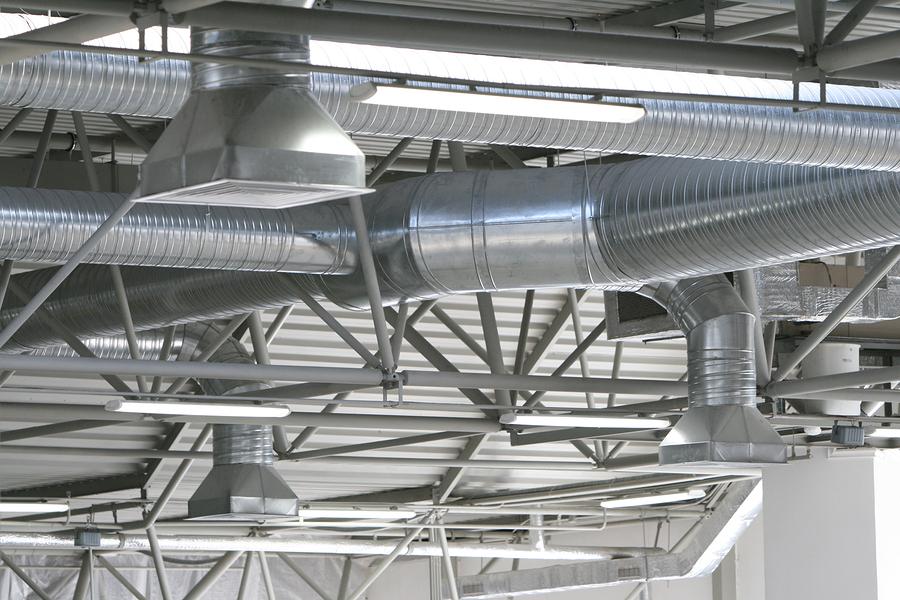

In small commercial buildings that have relatively simple layouts, standard ductwork tends to be sufficient for ensuring the acceptable delivery of heated and cooled air.

Manufacturers construct sheet metal out of a few different types of material. Galvanized is the most common one we hear of because it’s used in

Your air ducts bring in air when you use your air conditioning or heating system. If you are not using your air conditioner through the

Each batch of sheet metal is made to differing levels of strength, size, and thickness depending on the exact performance tests it has to pass.

How Custom Sheet Metal Is Used to Make Air Ducts Creating custom ductwork out of sheet metal is a process that can either be done