Can You Get Customized HVAC Sheet Metal Fabrication for Uniquely Designed Systems?

When it comes to customized HVAC sheet metal fabrication for uniquely designed systems, this option is not only available but also recommended by most HVAC

When it comes to customized HVAC sheet metal fabrication for uniquely designed systems, this option is not only available but also recommended by most HVAC

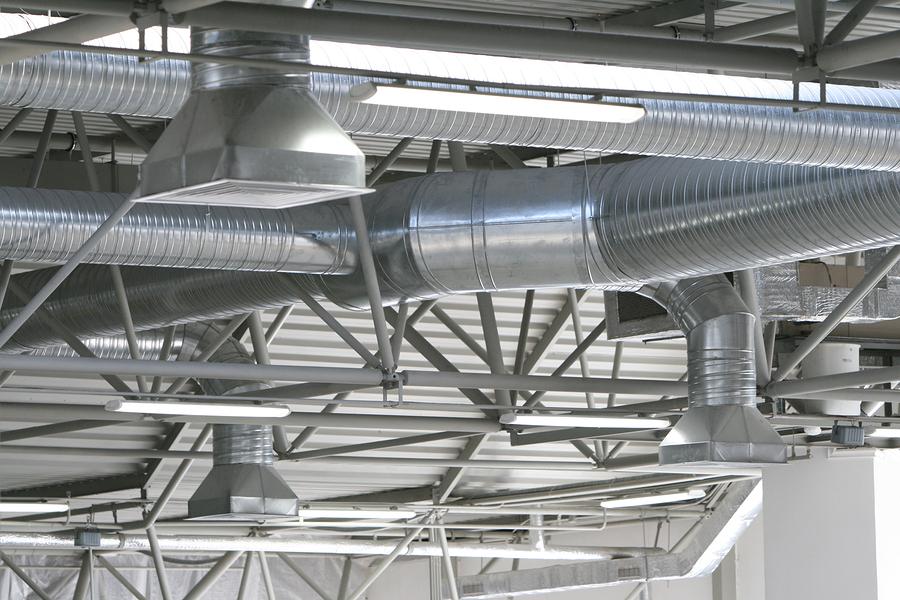

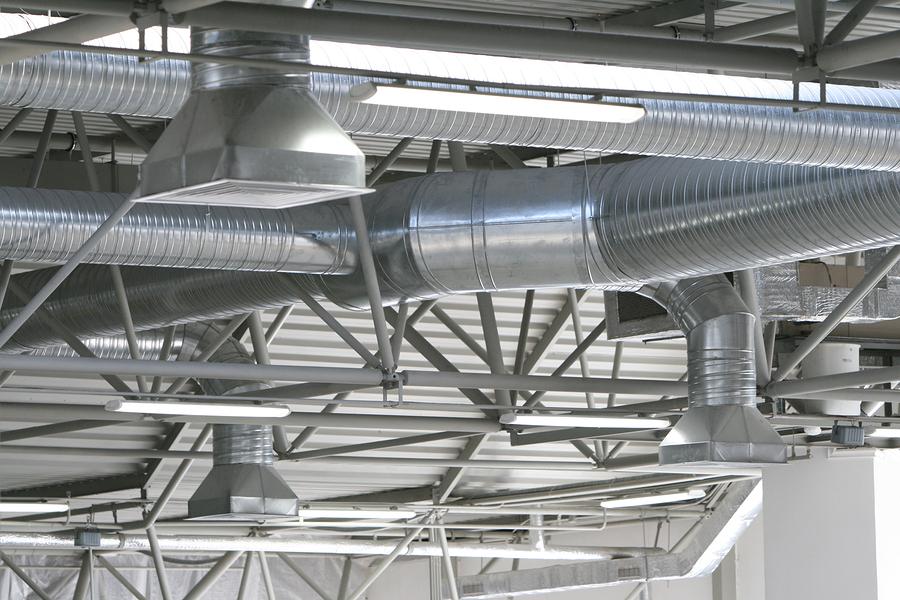

Ductwork is the networking of tubes that are connected to heating, ventilation, and air conditioning (HVAC) systems and run throughout homes. The purpose of ductwork

There are basically two types of ductwork. The first type, which is also the most frequently used, is rigid and often made of galvanized sheet

Sheet metal is an excellent choice for heating and cooling equipment because it enhances the performance of duct design components. Not only are sheet metal

We are a family-owned company with a team of dedicated technicians. Our contractors perform a slew of services, including HVAC for industrial, commercial, and residential

If you own commercial property, air conditioning maintenance and repair is often essential. Sometimes it becomes necessary to replace the duct work. Ductwork wears out

If you’re interested in making prototypes or even exact components, you don’t have to search for credible companies that can help you anymore. O.C. McDonald

Another few years have passed and now it’s time for you to perform maintenance on your HVAC system. It takes time and money, and then

When you are outside, you can breathe fresh air from all directions. In a building, you might receive the majority of your air from your

When facing sheet metal projects that need to be completed on commercial or residential buildings, it isn’t uncommon to wonder if the project can be