Is Hiring a Design/Build Mechanical Contractor More Efficient Than Breaking the Project Up?

There are many benefits to hiring a design and build mechanical contractor rather than just breaking the project up. It is important to think about

There are many benefits to hiring a design and build mechanical contractor rather than just breaking the project up. It is important to think about

As recent national disasters have shown, it is critical for businesses to include a disaster plan within a facility’s design. Just one catastrophic event can

San Jose, CA, technicians for office building ventilation air filters to eliminate microbial growth, dirt, or moisture contamination. Clean office building air prevents environmental health

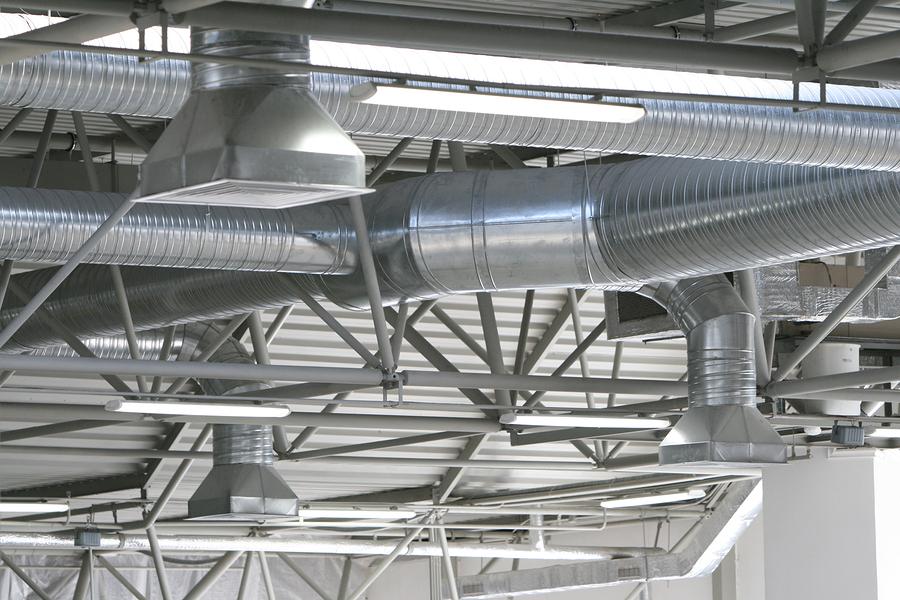

The heating and cooling system (HVAC) is among the most complex yet significant components of any building. Any malfunction and lack of proper maintenance can

MAINTAINING PROPER COMMERCIAL OR INDUSTRIAL BUILDING TEMPERATURE The importance of maintaining a comfortable atmosphere in a commercial or industrial business cannot be overemphasized. For a

When looking at duct-work, one does not think about all the work that goes into building them. Sheet metal fabrication is an art in itself

Benefits of Constructing Energy Saving Buildings Constructing an energy saving building saves a lot of money. This is seen when the building is constructed. It

Business owners and industrial managers who work in processing facilities know how important it is to get their feedstock or product from point A to