What Can Be Made With Custom Sheet Metal?

Custom sheet metal is developed through bending and cutting a metal sheet that is generally less than a quarter of an inch in thickness. Generally,

Custom sheet metal is developed through bending and cutting a metal sheet that is generally less than a quarter of an inch in thickness. Generally,

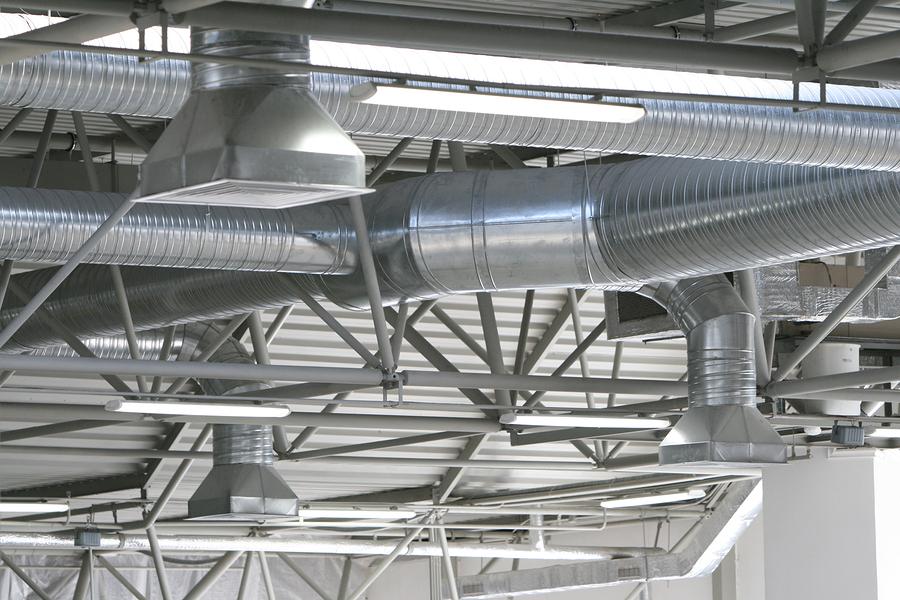

Sheet metal is an excellent choice for heating and cooling equipment because it enhances the performance of duct design components. Not only are sheet metal

When you are outside, you can breathe fresh air from all directions. In a building, you might receive the majority of your air from your

Sheets of metal are manufactured in different thicknesses. The thinnest pieces are aluminum foils used as kitchenware, and the thickest sheets are plates used as