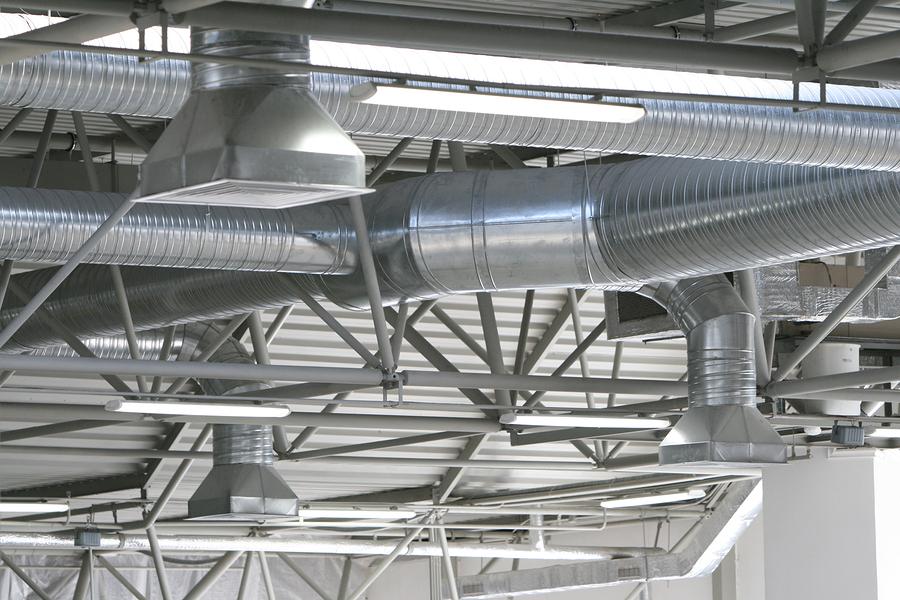

How Retrofit Commerical Ductwork Can Save Your Company a Lot of Money in the Long Run

No matter how well built your HVAC system is, at some point it will fail and require replacement. This can be a very time consuming

No matter how well built your HVAC system is, at some point it will fail and require replacement. This can be a very time consuming

No matter what your business specialty may be, the HVAC system throughout your facility can affect your company. Lack of proper maintenance of your heating,

Comprehensive management of equipment and services starts with operational assessment, which provides critical information to help business owners to plan for the future budget. The

When looking at duct-work, one does not think about all the work that goes into building them. Sheet metal fabrication is an art in itself

Regardless of the type of occupant, commercial or industrial facility owners and managers in Silicon Valley can spend a great deal of their maintenance budgets

Different Ways Educational Institutions Can Save Energy Educational institutions spend money to purchase energy systems. This is because the nature of educational institutions demands mass

Retrofitting Your HVAC System HVAC systems need to be replaced after being used for a certain period. This depends on the maintenance. Replacinthe HVAC system

Irrespective of how well a heating and cooling system is maintained, it’ll ultimately require replacement. This could not only disrupt your building’s operation for prolonged