What Can Be Made With Custom Sheet Metal?

Custom sheet metal is developed through bending and cutting a metal sheet that is generally less than a quarter of an inch in thickness. Generally,

Custom sheet metal is developed through bending and cutting a metal sheet that is generally less than a quarter of an inch in thickness. Generally,

If you’re interested in making prototypes or even exact components, you don’t have to search for credible companies that can help you anymore. O.C. McDonald

The building that your business occupies for years can prove to your customers that you are here to stay. But what happens when you experience

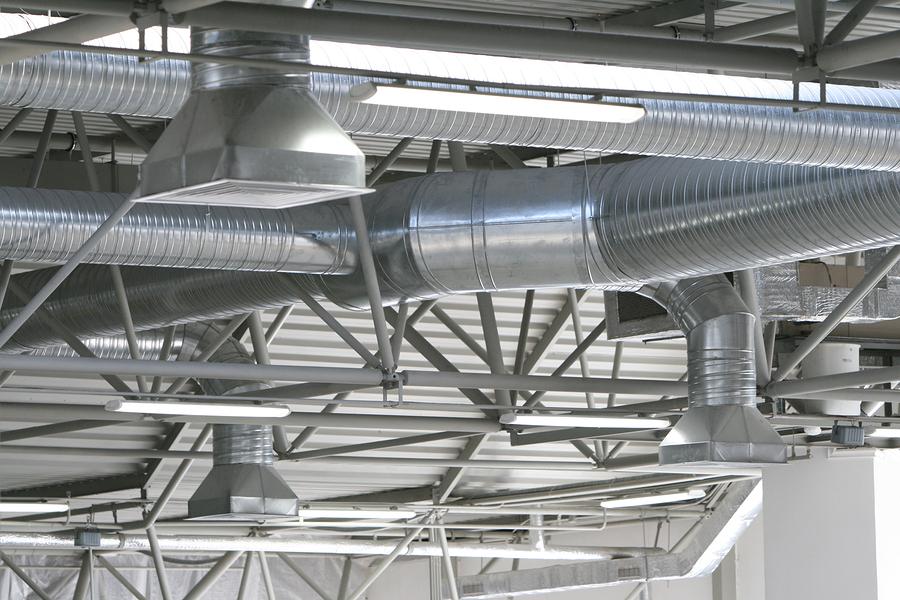

Fabricated sheet metal is commonly used in the ductwork of HVAC systems. Traditional ductwork is installed in commercial and industrial buildings for the heating and

Another few years have passed and now it’s time for you to perform maintenance on your HVAC system. It takes time and money, and then

When you are outside, you can breathe fresh air from all directions. In a building, you might receive the majority of your air from your

A new air conditioning unit can be a big expense for your home or business, but an old, inefficient unit incurs frequent repair costs and

Manufacturing any product out of metal requires sheet metal fabrication. It is the fundamental process of taking a plain sheet of metal and forming it

Top-Quality Pipefitting and Customized Sheet Metal Services Any job worth doing is worth doing right. That applies to pipefitting, sheet metal fabrication and beyond. If